Nitinol Alloys & Purities

Memry has an unparalleled history and scale in the Nitinol industry, starting in 1966 as the first commercial supplier of Nitinol to the Naval Ordinance Lab, which is where the “NOL” in NiTiNOL originated. The VIM + VAR nitinol melting process was established in 1990 through extensive superalloy experience to provide premium, repeatable quality by combining the advantages of VIM (homogeneity) and VAR (structure). This mature process continues today, outputting several hundred thousand pounds of clean, consistent material every year. Binary alloy formulations as well as ternary, quaternary and beyond are melted via this process, tailored to the users specific needs in heat sizes from 30 to 4000 pounds.

Alloys

We melt and produce Nitinol alloys in all common binary and ternary formulations. Custom formulations in binary, ternary, quaternary and beyond can be produced upon request. The table below depicts the most common Nitinol alloys:

Download Alloy Chart

Download Alloy ChartPurities

The presence of non-metallic inclusions and porosity is how the industry measures Nitinol microcleanliness. Typical non-metallic inclusions are carbides (TiC), and intermetallic oxides (Ti4Ni2Ox).

The size and distribution of these inclusions play a critical role for device designers who work with Nitinol. The size and area fraction of inclusions are precisely sampled and measured as detailed

here. This is an important consideration for medical and industrial high fatigue applications, but also for miniaturized products where inclusion size must be contained due to extremely fine structures.

While SAES standard purity Nitinol is suitable for most Nitinol devices, SAES offers two cleaner options in response to our customers’ needs for higher performance applications.

Redox is a second-generation material based on our standard Nitinol melting practice but carefully modified and controlled to limit oxide inclusion formation. Redox has been relied on by customers for over a decade.

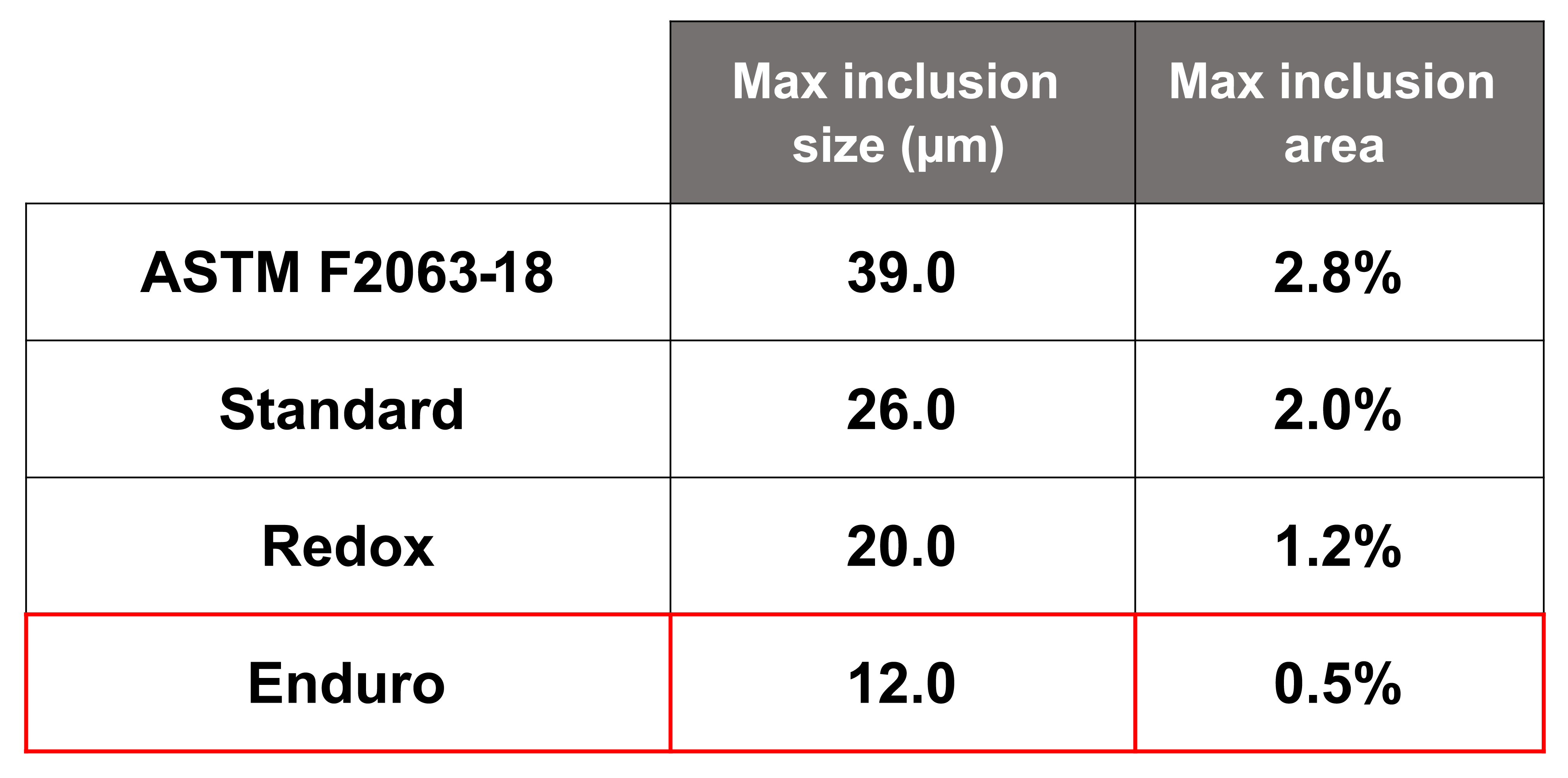

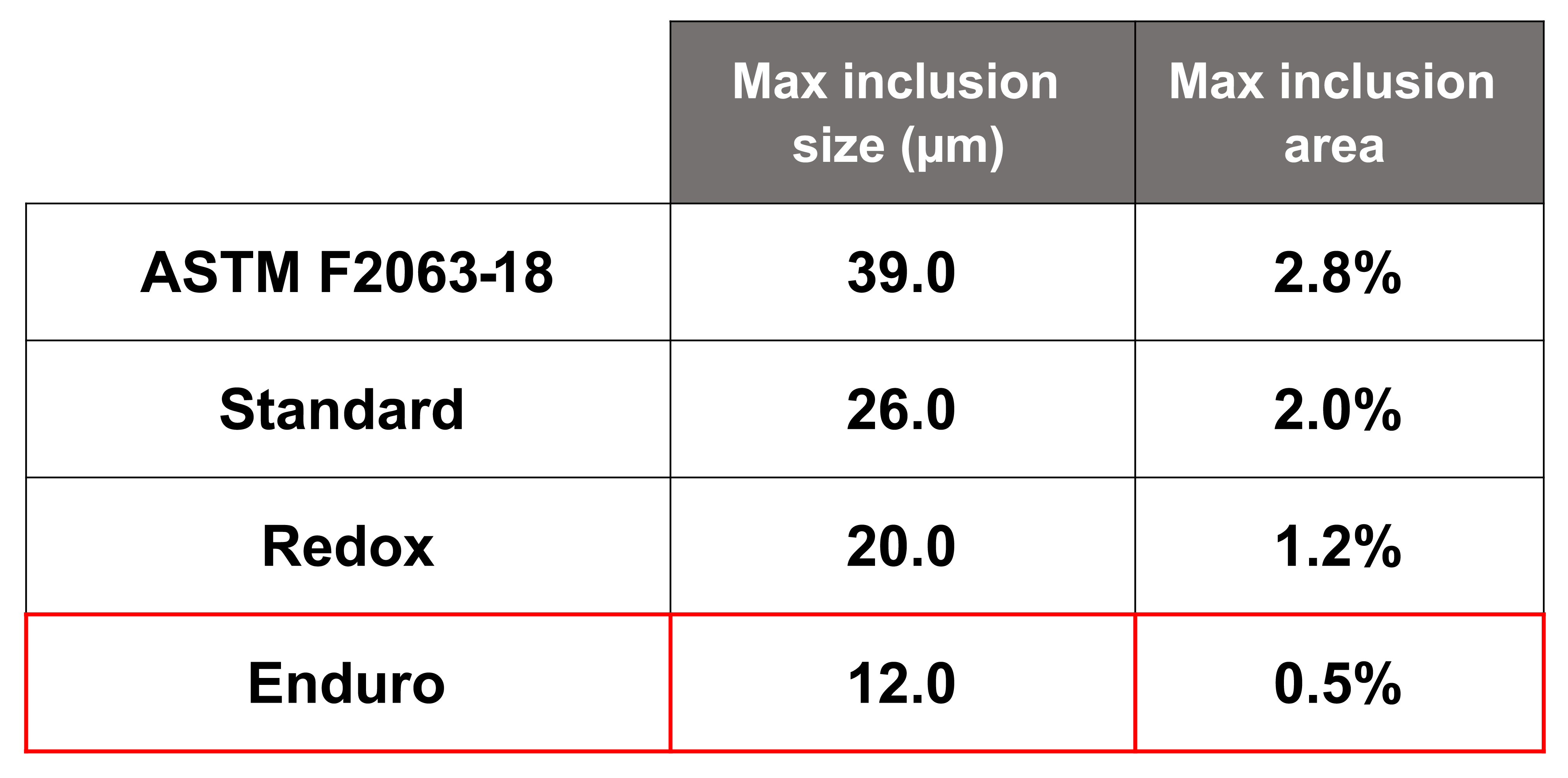

SAES’s cleanest offering, Enduro, is a third-generation material melted and processed using proprietary technology to deliver exceptional inclusion control that delivers maximum life in extreme applications. The table below shows ASTM allowable inclusion limits along with specifications for our standard, Redox and Enduro materials:

The table below shows comparative features of Standard, Redox and Enduro materials:

The histogram below demonstrates the differences between Standard and Enduro inclusions - showing a dramatic decrease in relatively large inclusions, leading to significantly improved fatigue life:

Download Enduro PDF

Download Enduro PDF